Loading... Please wait...

Loading... Please wait...

Store Navigation

- Home

- TECHNOLOGY

- SUPERFINISHED SURFACES

SUPERFINISHED SURFACES

THIS IS WHY SMOOTHER IS BETTER!

HEAT BUILD-UP - WHERE IT COMES FROM

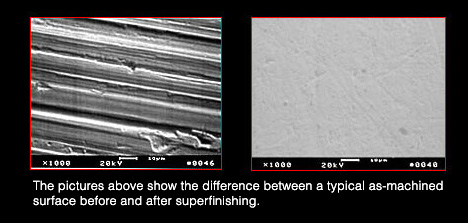

In engines and transmission assemblies, the moving parts rarely touch each other. The crankshaft in your engine does not actually ride on the main bearing surfaces, there is an oil film that separates the two surfaces. So to oversimplify things a bit here, we use lubricants to prevent parts from touching. So if things don’t touch, where does the heat come from? To answer that, let’s look at transmission gears. As machined, the gear surfaces are actually comprised of very small "peaks and valleys". As the gears rotate, the gear oil is pushed out from between those gear surfaces. As the oil is pushed out, a certain amount of turbulence is created as the oil has to navigate through those peaks & valleys. This turbulence causes the oil to work against itself and that friction heats up the gear oil.

REDUCING HEAT AND FRICTION - SMOOTHER IS BETTER

When it comes to machined parts, we all agree that smoother is better. That’s right, but remember that there are still “peaks & valleys” with turned, ground and even lapped surfaces and all create some degree of turbulence and increased heat. So it stands to reason that any process that removes those peaks will reduce the heat and friction.

REM® SUPERFINISHING - WHAT IT IS AND HOW IT WORKS

So how do we create a "peak-free" surface that doesn't change the size of the parts? In the past, that job was handled by time consuming hand polishing. But now there are a few processes that make that job much easier. Perhaps the most common is what most people refer to as the REM® or ISF® superfinishing system developed and patented by Rem Chemicals, Inc. Your parts are placed in a standard vibratory bowl that is filled with a non-abrasive, polished ceramic media. A chemical compound is introduced, that forms a 1 micron soft film on the surface. During the tumbling process, the film (on those peaks) is rubbed away, creating flat, peak-free surface. The result is a surface that has works as good as hand polished surfaces, but with a lot less work!

MICROBLUE ON SUPERFINISHED SURFACES - A TRULY AMAZING COMBINATION

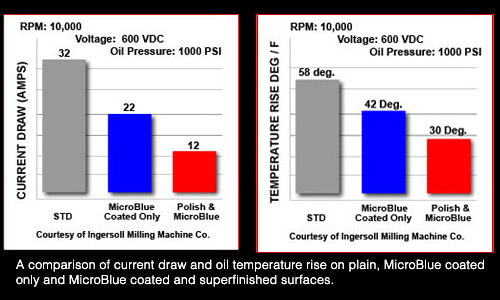

Now that we have surfaces that let oil move more freely, what if we put a coating on those surfaces that makes the lubricant work even better? Well MicroBlue does just that. And the results are nothing short of amazing. We've all heard the saying "one plus one equals three", this combination fits that description.

Years ago, in the development of MicroBlue, we were able to do some testing on a high-speed milling machine that used pressurized, oil film bearings that work the same way crank and rod bearings do. We were able measure the current draw on the DC motor as well as the temperature rise of the oil. After coating only, the reduction in friction and heat was impressive. But when we superfinished and coated the same parts, the improvement was stunning, as the charts show.

We knew right then and there this was an unbeatable combination. How well does this combination work? From feedback we've heard through the years, it's safe to say that whatever improvements (however it's measured) you see with superfinishing, you can pretty well double that when we bring MicroBlue into the equation. So on a final note we'd like to point out that polished surfaces are better. But they're only half as good as they could be.