Loading... Please wait...

Loading... Please wait...

Store Navigation

Bearing Removal

HERE'S SOME TIPS ON BEARING REMOVAL & INSTALLATION FROM CASES:

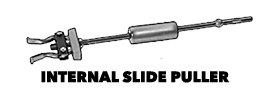

WHATS THE BEST WAY TO REMOVE BEARINGS FROM CASES?We are asked quite often which is the best way to remove bearings in cases and we are quick to point out that whenever possible, we use heat (and cold) and try at all costs not to use presses and/or pullers. The reason for this is it is far too easy to damage the bore the bearing is in especially if it's aluminum. But the "how much" and "how to" bring heat in is critical. We exclusively use an oven. Preferably a convection oven, where a fan circulates the heat and keeps things much more uniform. We typically place the items in an oven set at 350 deg./F. We place them so the bearings are at the top and quite often when they reach temperature, you'll hear them fall out. For most applications, we limit the oven time to 30 minutes An infrared temperature gun is very valuable here. If there are any bearings left in the cases, we (carefully) drop the cases on a hard floor from about 1". This usually dislodges the stubborn ones. In the event there's one being difficult, we prefer a slide puller, the one we use we purchased from McMaster Carr. |

|

A WORD ABOUT BALL BEARING "PRESS-FITS".Few people realize how critical the clearances either on the outer bearing bore or inner bore on bearing life and performance. Because if you have a shaft that's .001" larger than the bore, that inner race grows by that amount. Now take a bearing bore that's .001" smaller than the outer race and that outer race will now become smaller. Bear in mind that there needs to be enough clearance between the balls to allow space for the lubricant to work. If that clearance is not there, you are now forcing hard contact between the balls and races. The test we use to determine if all is well is to direct compresses air across the balls to initiate rolling. If the bearing turns freely, all is well. If it resists turning, it's time to check the clearances. |

|

|

IF YOU MUST USE FORCE... |

|

|

TO INSTALL BEARINGS, HEAT IS THE KEY. |

|

|

THINGS TO NEVER DO! 1) Never place aluminum parts on hot plates of any kind. It is next to impossible to heat evenly and even harder to control the temperature. Remember, when you approach 400 deg./F, (from metallurgical standpoint) you're in the danger zone. 2) Never use a torch of any kind, again for the above reasons, plus the fact that aluminum dissipates heat rapidly and you wind up overheating areas that also damages the metallurgy of the aluminum. 3) Never heat the bearing itself. It makes it grow and become harder to remove. 4) Never try to locally cool the bearing to shrink it. The cases will cool as well and everything gets tight.

|